General Requirements And Importance Of Drawings-Diagrams For Underground Power Cable Project

The employer may engaged or contract with service-provider to execute an underground power cable project, service-provider actually carry out the whole works as per employer requirements. Here in this article we would like to focus on general requirements and importance of various drawings, designs and calculation sheet to execute an underground power cable project.

The term “drawing” should also included here diagrams, schedules, performance curves, and calculations etc. required for the comprehensive design of the works. The Service Provider should be responsible for the provision of all drawings required for the various stages of the Contract to execute the project.

All drawings, apart from workshop drawings, should be submitted to the nominated Engineer for his approval, in accordance with an approved program.

The Service Provider should ensure that drawings are submitted for approval in prior enough time such that they may be approved within the specified period by the Engineer, prior to manufacture or construction commencing.

Further adequate time must be allowed by the Service Provider to permit any comments for revised or modification made by the Engineer to be incorporated.

Any works performed prior to approval of drawings by the Engineer will be entirely at the Service Provider’s own risk including any delays that may result from modifications being found to be necessary by the Engineer.

The numbers of drawings required and the method of issue should be mentioned in flow diagrams to specification that keep free from any confusion.

The Service Provider should be fully responsible for obtaining any drawing or data of existing plant and installations that he requires in order to carry out the works, and should also be responsible for verifying that any drawings of existing plant and installations are accurate.

The Service Provider should provide suitable drafting and other staff on site that he requires investigating and producing any drawings that he requires of existing equipment and installations in order to carry out the works.

Where existing installations have been modified or extended the Service Provider may provide complete new sets of drawings. In this respect the Service Provider should provide drawings detailing both the existing and new works and may not limit the scope of the drawings to the new works only.

What Should be Format of Drawings and Calculation Sheet ?

Sponsored:

Drawings are to be submitted for approval on paper prints, folded to A4 size with the project title-block and drawing numbers clearly visible. Details of the project title-block must be as per prior specified by employer.

All drawings are to be submitted on A series paper to ISO/5457. The maximum size of drawings should be A1 except for site survey and layout drawings which may be submitted as A0 size sheets, if necessary, to accommodate details on a scale of 1:100. Single line diagrams and schematic drawings should preferably be on a maximum sheet size of A2. All dimensional drawings should be the following scales and detailed.

-

1:1, 1:2, 1:5, 1:10 and factors of 10 thereof;

-

Drawings symbols should be in accordance with IEC 117.

-

All drawings are to be submitted in Auto Cad format in CDR Disk.

-

Drawing titles should clearly identify the specific function of the drawings and where appropriate the name of the site(s) to which the drawing applies.

|

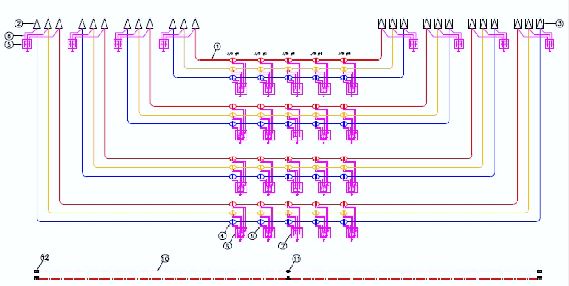

| Cable Schematic Line Diagram |

How Follow Drawing Numbering and Revisions?

The Service Provider should be responsible for adding the nominated Engineers drawing numbers to all drawings prior to submittal. Following award of the contract the Engineer and Service Provider will review the numbering system, familiarize with each other requirements, and agree on the numbering system to be applied.

Comprehensive cross-reference are to be included on drawings and the Service Provider should include the Engineer’s drawing number in the cross-references.

At each and every issue of a drawing the revision should be raised, and details given in revision boxes on the drawings. Comprehensive details of revisions are to be given and phrases such as “REVISED”, “UPDATED”, “MODIFIED” or similar are not acceptable.

Reference to any drawing in communications should include the Engineer’s drawing number.

Drawing Submittals and Approvals Procedure

The Service Provider should submit drawings for the plant and works for formal approval to the nominated Engineer. A program of drawing submittal should be agreed with the Service Provider following the contract award.

Drawings issued in accordance with this program should take account of the time periods necessary for postage, and approved by the Engineer, to ensure that approved drawings are available prior to manufacture the materials for the project execute. For site construction works, “Construction Issues” drawings are to be available, on site, at least 21 days prior to the commencement of the works.Where appropriate the drawings should be accompanied by supporting calculations.

Following examination the Engineer should allocate a status on drawings. The subsequent action and distribution of drawings will depend on the status given by the Engineer as detailed below.

“Approved”, the details of the drawing have been checked by the Engineer and appear to comply with the requirements of the specification. Once approved the Service Provider should raise the revision to indicate Approved by the Engineer on Mark the drawing “Construction Issue” and distribute as per employer requirement that mentioned in contract.

“Approved Subject to Comment”. The drawing has been examined by the Engineer, and apart from the minor details can be considered Approved subject to the Service Provider making the amendments required by the Engineer. The Service Provider may issue the drawing as “Approved” as outlined above without resubmitting to the Engineer for formal approval, provided the corrections have been made as required.

“Examined and Returned with Comments”. The drawing is considered to be revised by the Service Provider and immediately resubmitted to the Engineer for approval.

“Examination not required”. The drawing not requiring approval by the Engineer has been examined by the Engineer. Examples of typical drawings of this nature are: equipment schedules and diagrams of connections. Drawings returned to the Service Provider of this status should be stamped “For information only” and “Construction Issue” and issued in the same manner as Approved drawings.

Approval of a drawing by the Engineer must in no way to relieve the Service Provider of his responsibilities under the Contract.

Service Provider may revise a drawing for any reason following approval by the Engineer, the revised drawing is to be resubmitted for re-approval by the Engineer, the original approval automatically being void.

The Service Provider must submit, marked-up copies of the drawing issue programmed indicating the up to date status on drawing submittal and approval on a monthly basis. In addition the Service Provider should submit a schedule of the total number of drawing submitted, together with the total numbers of each of the above categories. An “S” curve is also to be submitted indicating the total number of planned approved drawing together with the actual numbers to date.

Sponsored:

Sponsored:

As Built Recorded Drawing and Construction Amendment for Project

During construction of the Works on the site, the Service Provider should ensure that all departures, modifications and corrections to the approved drawings are recorded. All such changes to the drawings are to be marked in red to show on “as-built” stated and one set of “as-built” drawing are to be available on the site at all times.

If Service Provider wish to make modifications as per site requirement on the approved construction drawings which influence the operation of the Plant, he should obtain the approval of the Engineer’s representative prior to instituting the modifications.

Following examination of the “as-built” drawing the Engineer’s representative should return one copy to the Service Provider indicating approval of the construction modifications, or further modifications required to satisfy the requirements of the specifications.

Record Drawing for Cable Line Construction Project

On receipt of Approval of “as-built” drawings, the Service Provider be responsible for the production of Record Drawings for the complete plant on each section of the Works.

The Service Provider should modify the revision to “As-Built” and “Record Drawing” for all drawings applicable to the section of the works and submit these for approval to the Engineer.

On receipt of the Engineer’s approval the Service Provider will provide sets of paper prints of each drawing as detailed on pre-specification of the contract. Any contract drawing included in the Operation and Maintenance manuals should also be revised in accordance with any “as-built” modifications and re-issued.

These sets of record drawings should be issued within 90 days of the Taking-over of the completed plant.