What is Safety Extra-Low Voltage (SEVL)?

Safety by extra low voltage SELV is used in situations where the operation of electrical equipment presents a serious hazard like swimming pools, amusement parks, etc. The impulse withstand level of insulation between the primary and secondary winding is very high. The secondary voltage never exceeds 50 V rms.

Three conditions of exploitation must be respected in order to provide satisfactory protection against indirect contact:

- No live conductor at SELV must be connected to earth;

- Exposed-conductive-parts of SELV supplied equipment must not be connected to earth, to other exposed conductive parts, or to extraneous-conductive-parts;

- All live parts of SELV circuits and of other circuits of higher voltage must be separated by a distance at least equal to that between the primary and secondary winding of a safety isolating transformer.

The use of PELV (Protection by Extra Low Voltage):

This system is for general use where low voltage is required, or preferred for safety reasons. The conception is similar to that of the SELV system, but the secondary circuit is earthed at one point.

Protection against direct contact hazards is generally necessary, except when the equipment is in the zone of equipotential bonding, and the nominal voltage does not exceed 25 V rms, and the equipment is used in normally dry locations only, and large-area contact with the human body is not expected. In all other cases, 6 V rms is the maximum permitted voltage, where no direct contact protection is provided.

|

| Low-voltage supplies from a safety isolating transformer |

What is FELV system (Functional Extra-Low Voltage)?

Where, for functional reasons, a voltage of 50 V or less is used, but not all of the requirements relating to SELV or PELV are fulfilled, appropriate measures must be taken to ensure protection against both direct and indirect contact hazards, according to the location and use of these circuits.

The electrical separation of circuits:

Sponsored:

The electrical separation of circuits is suitable for relatively short cable lengths and high levels of insulation resistance. It is preferably used for an individual appliance.

The principle of the electrical separation of circuits (generally single-phase circuits) for safety purposes is based on the following rationale.

The two conductors from the unearthed single-phase secondary winding of a separation transformer are insulated from earth.

If a direct contact is made with one conductor, a very normal current only will flow into the person due to normal inherent capacitance to earth and will back to the other conductor. As the length of circuit cable increases, the direct contact current will progressively increase to a point where a dangerous electric shock will be experienced.

Transformers are specially designed for this duty, with a high degree of insulation between primary and secondary winding, or with equivalent protection, such as an earthed metal screen between the winding. Construction of the transformer is to class II insulation standards.

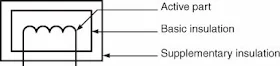

Class II equipment:

These appliances are also referred to as having “double insulation” since in class II appliances a supplementary insulation is added to the basic insulation.

|

Principle of class II insulation leve |

Most portable or semi-fixed equipment, certain lamps, and some types of transformer are designed to have double insulation. Electronic devices, radio and television sets have safety levels equivalent to class II, but are not formally class II appliances

Out-of-arm’s reach or interposition of obstacles:

Sponsored:

By these means, the probability of touching a live exposed-conductive-part, while at the same time touching an extraneous-conductive-part at earth potential, is extremely low.

In practice, this measure can only be applied in a dry location, and is implemented according to the following conditions:The floor and the wall of the chamber must be non-conducting,

In practice, this measure can only be applied in a dry location, and is implemented according to the following conditions:The floor and the wall of the chamber must be non-conducting,

|

| Protection by out-of arm’s reach arrangements and the interposition of non-conducting obstacles |

Earth-free Equipotential Chambers:

In this scheme, all exposed-conductive-parts, including the floor are bonded by suitably large conductors, such that no significant difference of potential can exist between any two points.

A failure of insulation between a live conductor and the metal envelope of an appliance will result in the whole “cage” being raised to phase-to-earth voltage, but no fault current will flow. In such conditions, a person entering the chamber would be at risk (since he/she would be stepping on to a live floor).

A failure of insulation between a live conductor and the metal envelope of an appliance will result in the whole “cage” being raised to phase-to-earth voltage, but no fault current will flow. In such conditions, a person entering the chamber would be at risk (since he/she would be stepping on to a live floor).

|

| Equipotential bonding of all exposed-conductive-parts simultaneously |

Source:http://www.electrical-installation.org

No comments:

Post a Comment

WAZIPOINT:

Thank you very much to visit and valuable comments on this blog post. Keep in touch for next and new article. Share your friends and well-wisher, share your idea to worldwide.