Transformer testing is important for you if you work with the transformer as a transformer manufacturer, Transformer supplier, transformer Service Company or transformer user power consumer, or transformer user as a Utility Company. But, you do not need to carry out all kinds of transformer tests; depending on your service category transformer testing procedure and transformer testing tools and equipment will be different.

Depending

on the transformer test frequency, you may own transformer testing equipment or a test bench and you can do a test by your own arrangement. On the other hand, you

may take help from transformer testing companies, they have all transformer

test set facilities with a well-furnished testing lab. They will provide you with a transformer test certificate mentioning the test result after testing the

transformer in their transformer test laboratory.

Why

Transformer Test is required?

If

you are a transformer manufacturer or transformer user, you must manufacture or

purchase a predesigned and specified transformer to fulfill your client or your

requirement where a transformer quality test or transformer commissioning test is

important. So to confirm the specifications and performances of an electrical

power transformer you have to go through a number of testing procedures. The transformer manufacturer will carry out some tests at a transformer manufacturer's premises

before delivering the transformer. The transformer user end also needs some transformer

tests before commissioning.

Two

main types of transformer testing – type test of transformer

and routine test of the transformer are performed in the manufacturer

test bench.

Type

of Transformer Testing at Factory and User End

Generally, the factory carried out some routine tests and type tests carried out by a third party

like the STL member testing company, End Users normally carried out pre-commissioning

and commissioning tests after installation of the transformer.

A. Transformer Tests were done at the factory

To

ensure the client’s requirement transformer manufacturer need to carry out some

type of test, routine test, and special test at the factory end before delivering the

transformer to the client. Confirming

the basic design expectation of the transformer some tests are carried is done

mainly in a prototype unit not in all manufactured units in a lot. Transformer Type Test confirms the main and basic design

criteria of a production lot. Transformer Routine Test

is carried

out on every unit manufactured mainly for confirming the operational

performance of the individual unit.

1. Transformer Type

tests

a) Winding resistance test of the transformer;

b) Transformer ratio test;

c) Transformer vector group test;

d) Measurement

of impedance voltage/short circuit impedance (principal tap) and load loss

(Short circuit test);

e) Measurement

of no-load loss and current (Open circuit test);

f) Measurement

of insulation resistance;

g) Dielectric tests of the transformer;

h) Temperature rise test of the transformer;

i) Tests

on on-load tap-changer;

j) Vacuum

tests on tank and radiators.

2. Transformer Routine

tests

a) Winding resistance test of the transformer;

b) Transformer

ratio test;

c) Transformer vector group test;

d) Measurement

of impedance voltage/short circuit impedance (principal tap) and load loss (Short circuit test);

e) Measurement

of no-load loss and current (Open circuit test);

f) Measurement of insulation resistance;

g) Dielectric

tests of the transformer;

h) Tests

on on-load tap-changer;

i) Oil

pressure test on the transformer to check against leakages past joints and gaskets.

3. Transformer Special

tests

a) Dielectric

tests;

b)

Measurement

of the zero-sequence impedance of three-phase transformers;

c)

Short-circuit

test;

d)

Measurement

of acoustic noise level;

e)

Measurement

of the harmonics of the no-load current;

f)

Measurement

of the power taken by the fans and oil pumps;

g)

Tests

on bought-out components/accessories such as Buchholz relay, temperature indicators, pressure

relief devices, oil preservation system, etc.

B. Transformer Tests were done at the site

Transformer

Site Acceptance Tests or SAT tests are carried out at the site after installing

the Transformer, the actual commissioning of the transformer at the site. Before

energizing the transformer, a pre-commissioning and commissioning test is

required to confirm the performance.

1.

Pre-commissioning

tests;

2.

Periodic/condition

monitoring tests;

3.

Emergency

tests.

Winding Resistance Test of Transformer

The resistance of each winding, the terminals between which is measured and the temperature of the windings shall be recorded.

A direct current shell is used for the measurement. In all resistance measurements, care shall be taken so that self-inductive effects are minimized.

During that cold resistance measurements, the time for measuring current to become steady should be noted and used for guidance when making hot resistance measurements following a temperature rise type test.

Transformer winding resistance measurement is carried out as a type-test, routine test, and also as field test.

Transformer winding resistance measurement helps in determining the following:

- Calculation of the I2R losses.

- Calculation of winding temperature at the end of temperature rise test of transformer.

- As a benchmark for assessing possible damages in the field

Principles of Operation

The basic idea is to inject a DC current through the winding to be measured, and then read

the voltage drop across that winding.

Electrical Testing Instruments apply the dc current through the winding and an internal

standard current shunt. After both DC voltage drops are measured they are ratioed and the

display is read as resistance on the front panel meter. This method allows for the lead

resistance to be omitted since the reading is independent of the current. In addition, no

multiplication factors will be needed when changing the current ranges.

The DC current source must be extremely stable. Refer to the formula for DC voltage across a

transformer below:

v = I * R + (L di/dt)

where,

vdc = voltage across transformer winding

I = DC current through transformer winding

R = resistance of the transformer winding

L = inductance of the transformer winding

di/dt = changing value of current (ripple)

Assume that the tester has a very stable current source (i.e., no ripple), then di/dt is zero and

the term L di/dt becomes zero.

Transformer Ratio Test

First of all, isolate all types of equipment, connect groundings to all incoming and outgoing cables and disconnect all incoming and outgoing cables from the transformer bushing terminals connections.

Connect the H-designated three-phase test lead with the military-style connector at one end to the mating connector on the test set marked with an H. Ensure that the connector’s index notch lines up properly.

Connect the X-designated three-phase test of the lead military-style connector at one end to the mating connector on the test set marked with an X. Ensure that the connector’s index notch lines up properly.

Connect the H1, H2, H3 designated test lead to the corresponding H1, H2, H3 transformer terminal/bushing. Connect the H0 test lead if H0 terminal/bushing is present.

Connect the X1, X2, X3 designated test leads to the corresponding X1, X2, X3 transformer terminals/bushings. Connect the X0 test lead if X0 terminal/bushing is present.

Perform turns ratio measurements for all tap positions.

Confirm that the measured ratios are within 0.5% of the calculated ratios.

Transformer Vector Group Test

Connect the neutral point of star-connected winding with the earth. Join 1U of HV and 2W of LV together. Measure voltages between terminals 2U-1N, 2V-1N, 2W-1N, which means voltages between each LV terminal and HV neutral.

Let’s consider a YNd11 transformer.

1) Connect the neutral point of star-connected winding with the earth.

2) Join 1U of HV and 2W of LV together.

3) Apply 415V, three-phase supply to HV terminals.

4) Measure voltages between terminals 2U – 1N, 2V – 1N, and 2W – 1N, which means voltages between each LV terminal and HV neutral.

5) Also measure voltages between terminals 2V – 1V, 2W – 1W and 2V – 1W. For YNd11 transformer, we will find, 2U – 1N > 2V – 1N > 2W – 1N 2V – 1W > 2V – 1V or 2W – 1W

The vector group test of the transformer for another group can also be done in a similar way.

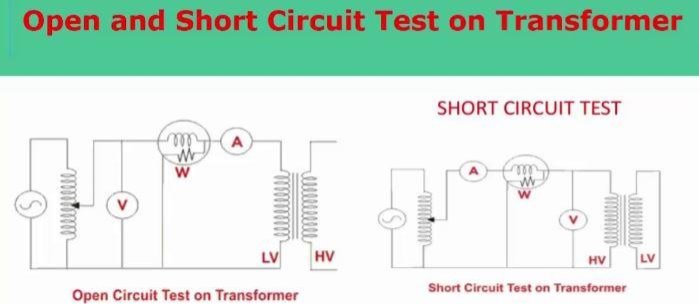

Transformer Short Circuit Test

Transformer short circuits and open circuit tests are very much common to everyone who jobs on the related transformer. Almost every transformer repairing workshop have transformer testing for short circuit and transformer testing for open circuit.

The connection diagram for the transformer short circuit test diagram on the transformer is shown in the common figure above.

Required tools for transformer short circuit:

The above meters are connected to the HV side of the transformer as shown in the diagram. Around 5-10% low voltage is applied to that HV side using a variac (i.e. a variable ratio autotransformer).

The LV side of the transformer is shorted using a wire. Now from the variac applied voltage is slowly increased until the wattmeter, and an ammeter gives a reading equal to the rated current of the HV side.

After reaching HV side rated value, record Voltmeter, Ammeter, and Watt-meter readings. The ammeter reading gives the primary equivalent of full load current IL. As the voltage applied for full load current in a short circuit test on the transformer is quite small compared to the rated primary voltage of the transformer, the core losses are negligible here.

Transformer short circuit test example

Let’s consider,

Ammeter reading IL is short circuit current;

voltmeter reading is Vsc, which is short circuit voltage;

wattmeter reading is Psc, input power during the test.

Let us consider.

Where Re is the equivalent resistance of the transformer.

If, Ze is the equivalent impedance of the transformer.

Therefore, if the equivalent reactance of the transformer is Xe.

Though the test is conducted at the high voltage end, so these values are referred to as the HV end of the transformer. to get the value of the low voltage end just divide these values by the square of the transformation ratio.

The short-circuit test of a transformer actually determines the copper losses in the transformer at a full load that can use to find the parameters to approximate the equivalent circuit of a transformer.

Transformer Open Circuit Test

Similar to the short circuit test of the transformer, open circuit testing of the transformer is also important and very common for transformer users.

The connection diagram for transformer open circuit testing is shown in the common figure above.

Testing tools for transformer open circuit test

The above meeters have connected in the LV side of the transformer as the connection diagram above. The voltage at rated frequency is applied to that LV side using a variac that a variable ratio autotransformer and HV side of the transformer is kept open.

Now apply the rated voltage of the LV side using a variac and record Voltmeter, Ammeter, and Wattmeter readings.

Transformer open circuit test

The ammeter reading gives the no-load current Ie.

Ie is quite small so the voltage drops due to this current can be taken as negligible.

Since the voltmeter reading V1, is the secondary induced voltage of the transformer,

Wattmeter reading Po indicates during the no-load condition.

Hence, can take the wattmeter reading as equal to the core losses in the transformer.

Let us consider the wattmeter reading is Po.

Where Rm is the shunt branch resistance of the transformer.

If, Zm is the shunt branch impedance of the transformer.

Therefore, if the shunt branch reactance of the transformer is Xm,

These values are referred to as the LV side of the transformer due to the tests being conducted on the LV side of the transformer. These values could easily be referred to as the HV side by multiplying these values with the square of the transformation ratio.

Therefore it is seen that the open circuit test on the transformer is used to determine core losses in the transformer and parameters of the shunt branch of the equivalent circuit of the transformer.

Measurement of insulation resistance of Transformer

The power and Distribution Transformer Test Laboratory frequently uses the transformer IR test or Insulation Resistance test. It is very simple like other electrical circuits or equipment's IR test.

Transformer insulation resistance test or IR test carry out simply using an Insulation Resistance tester or Megger (Megha Ohm measuring tools).

The procedure of the Insulation Resistance Test of the Transformer

Measures the insulation resistance of HV & LV winding with respect to earth (body) and between LV & HV winding. Recommended Values are 2000 Mohms for HV and 500 Mohms for LV:

Transformer IR value calculating formula considering phase:

| Transformer | Formula |

| 1-Phase Transformer | IR Value (MΩ) = C X E / (√KVA) |

| 3-Phase Transformer (Star) | IR Value (MΩ) = C X E (P-n) / (√KVA) |

| 3-Phase Transformer (Delta) | IR Value (MΩ) = C X E (P-P) / (√KVA) |

| Where C= 1.5 for Oil-filled T/C with Oil Tank, 30 for Oil-filled T/C without Oil Tank, or Dry Type T/C. |

Transformer IR value calculating formula considering rated voltage:

| Voltage | Test Voltage (DC) LV side | Test Voltage (DC) HV side | Min IR Value |

| 415V | 500V | 2.5KV | 100MΩ |

| Up to 6.6KV | 500V | 2.5KV | 200MΩ |

| 6.6KV to 11KV | 500V | 2.5KV | 400MΩ |

| 11KV to 33KV | 1000V | 5KV | 500MΩ |

| 33KV to 66KV | 1000V | 5KV | 600MΩ |

| 66KV to 132KV | 1000V | 5KV | 600MΩ |

| 132KV to 220KV | 1000V | 5KV | 650MΩ |

- First, disconnect all the line and neutral terminals of the transformer;

Megger leads to be connected to LV and HV bushing studs to measure insulation resistance IR value in between the LV and HV windings;

Megger leads to be connected to HV bushing studs and transformer tank earth point to measure insulation resistance IR value in between the HV windings and earth;

Megger leads to be connected to LV bushing studs and transformer tank earth point to measure insulation resistance IR value in between the LV windings and earth.

Dielectric tests of power transformer

Transformer dielectric test is generally performed in two different steps:

Separate source voltage withstand test;&

Induced voltage withstands the test.

Separate Source Voltage Withstand Test of Transformer

This Transformer's main insulation to earth and between winding is ensured to perform the separate source withstand the test of the transformer. The procedure of separate source voltage test is as below:

To perform this test connect all of the three-line terminals of the winding together;

Other non-testing winding terminals and a tank of the transformer should be connected to the earth;

The transformer testing terminal winding is connected for around 60 seconds to a single-phase power frequency voltage that shape approximately sinusoidal;

One by one perform the test for all windings;

The test is successful if no breakdown.

Induced voltage test of transformer

You may check the inter-turn and line end insulation as well as main insulation to earth and between windings using the method of insulated voltage test of a transformer. The procedure of the induced voltage test of the transformer is as below:

Keep the primary winding of the transformer open;

A three-phase voltage having twice the rated voltage of secondary winding in magnitude and frequency should apply to the secondary winding;

The duration of the test shall be 60 seconds;

The test shall start with a voltage lower than 1/3 the full test voltage, and it shall be quickly increased up to the desired value.

The value of the transformer test voltage is as below:

Nominal system voltage rating for equipment | Highest system voltage rating for equipment | Rated short duration power frequency withstand voltage |

| 415V | 1.1 KV | 3 KV |

| 11 KV | 12 KV | 28 KV |

| 33 KV | 36 KV | 70 KV |

| 132 KV | 145 KV | 230 / 275 KV |

| 220 KV | 245 KV | 360 / 395 KV |

| 400 KV | 420 KV | 570 / 630 KV |

Temperature rise test of transformer

The transformer temperature rise test is normally included in the type test of the transformer. The voltage is applied to the HV winding of the transformer so that power input is equal to no-load losses plus load losses corrected to a reference temperature of 75oC.

Factors Affecting Winding Temperature Rise:

- Winding resistance measuring equipment;

- Ambient temperature determination;

- Inadequate calculation of the average oil temperature (leads to the wrong factor);

- Accuracy of Load Loss measurement;

- Assumed total loss as the sum of NL + LL;

- Effect of the Core temperature dynamics;

- Cold resistance measurement errors;

- Not reaching steady-state before shutdown.

Transformer Test on ON-LOAD tap-changer

The purpose of a tap changer in a power transformer is to regulate the output voltage. The working principle of a tap-changer just alters the number of turns transformer one winding and thereby changes the transformer turns ratio.

Transformer tap changing actually has two types:

- an on-load tap changer in short OLTC;&

- a de-energized tap changer in short DETC.

A low (DC) test current through the on-load tap changer is used during dynamic resistance measurements. This method is, in particular, sensitive to maintenance errors, contact degradation, and contact timing problems. In general, a distinction can be made between defects that interrupt the current through the OLTC, defects that affect the timing of the OLTC contacts, and contact degradation resulting in abnormal contact resistance.

Usually, winding resistance measurements are performed on offline power transformers. In the case of the on-load tap changer, which permits tap changing and hence regulates voltage without interrupting the load current, a dynamic resistance measurement can be performed during the operation of OLTC to find degradation and defects inside the OLTC.

Vacuum test on the Tank and Radiators of the Transformer

Vacuuming Procedure:

- When the transformer is to be filled or topped off in the field, it must be filled under vacuum according to specific instructions;

- The transformer should not be left under vacuum except during the vacuum filling operation;

- Leaks in the temporary piping and connections lead to the danger of drawing moisture into the tank if it is under vacuum during periods of high humidity or during rain;

- It is recommended that the tank is under positive pressure during rain to prevent drawing moisture into the tank.

Transformer Vacuum Type Test:

| 3 ¢ Transformers Up to 200 kVA | 250mm of Hg. for

30 minutes |

3 ¢ Transformers

>200kVA &

up to 2500kVA

| 500mm of Hg. For

30 minutes |

Oil pressure test on the transformer to check against leakages past joints and gaskets.

Oil pressure test on the transformer to check against leakages past joints and gaskets. That means Routine tests of the transformer include all the type tests except temperature rise and vacuum tests. The oil pressure test on the transformer to check against leakages past joints and gaskets are included.

Oil Leakage Type test

- Non-sealed & sealed Type Transformers: The pressure of Twice the normal head

measured at the base of the tank for 8 hours

- Tank with corrugations: The pressure of 15kPa was measured at top of the

tank for 6 hours.

Transformer oil leaking is dangerous for equipment as well as the environment getting the Leaking oil onto the ground and into groundwater. It can be expensive to remedy, Transformer leaking oil can carry lead from transformer paint into the ground causing further contamination.

Measurement of the zero-sequence impedance of the three-phase transformer

The zero-sequence impedance is usually measured for all star-connected windings of the transformer. The measurement is carried out by supplying a current of rated frequency between the parallel-connected phase terminals and the neutral terminal.

Procedure:

1st connect all phases in parallel (see C B A), and connect to AC Generator(single-phase GS or G1).

2nd neutral Transformer(T1) is connected to the return or neutral path of the generator

3rd place 1 CT(T3) in series with the parallel-connected CBA line

4th connect Ammeter(P3) at secondary of series CT(T3)

5th connect 1 PT(T2) across CBA and Neutral path of Transformer and connect voltmeter(P2) in secondary of this PT

7th, winding not under test remains open (see 2C,2B,2A, and 2N)

8th Apply current with frequency, now the question is how much current we need to employ, for that purpose you must have a knowledge of neutral current because you need to inject Io=3 In, but it is very dangerous to that amount of current in the transformer as the temperature of the excessive metallic part will increase, so what engineers will do, he just inserts the percentage of current, and then calculate the value by extrapolation

We can calculate impedance after taking a reading from an Ammeter and Voltmeter or our test kit process calculation of zero impedance by below mentioned series of formulae

In=3Io…..(1)

Vn=3Vo…..(2)

In we will find from Ammeter, and Vn will be found from the Potential or voltmeter. From these values, we will find Vo and Io, and zero sequence impedance will be found by the below formula,

Vo =-Io*Zo

Z0=-(Vo/Io)

In star connection, Zo reading is in the percentage of around 30% to 60% of rated phase impedance. Test findings will be compared with data or ratings as stated in the above mention statement.

Measurement of the acoustic noise level of a Transformer

The Transformer noise level is measured basically using two methods:

- sound pressure measurement;&

- sound intensity measurement.

There are three physical phenomena that produce noise in the magnetic core :

1. The movement of the 90-degree Bloch walls inside the magnetic domains, frequently called Magnetoacoustic

Emission (MAE); see Figure 1.

2. The rotation of the magnetic domains is responsible for the bulk magnetostriction; see Figure 2.

3. The Lorentz Force Acoustic Signal (LFAS) causes mechanical forces between laminations of the core; see Figure 3.

Sound pressure method:

The intent of this test is to report the spatially averaged total A-weighted sound pressure level for each power option accompanied by a single spatially-averaged frequency spectrum. The same test procedure applies, either a walkthrough or point-by-point procedure, for both background noise measurements and test measurements. A spatially-averaged total background noise level and the corresponding frequency spectrum shall be recorded immediately before and after each test measurement sequence. If the background noise level is at least 10 dB lower than that of the test object, then the background noise can be measured at a single location on the prescribed contour and no background noise correction is necessary.

Method sound intensity:

The noise level is commonly measured in decibels (dB) by comparing the pressure generated by a noise source with some standard level. The noise level is basically measured by two methods, the sound pressure measurement, and the sound intensity measurement. The noise level measurements in CPRI are carried out using the sound pressure method. The test methods and the acceptable conditions of the test environment are specified in IEC: 60076-10. The methods are applicable to transformers, reactors, and their cooling devices as well. The sound pressure level is a scalar quantity and requires simple instrumentation. Sound intensity is a vector quantity and the method measures directional sound. Therefore, it is less affected by background noise. Therefore, the sound intensity method can provide more accurate measurements in the presence of background noise.

Measurement of the harmonics of a Transformer at no-load current

Traditionally, transformer losses are divided into no-load losses and load losses as described earlier. The same loss grouping is retained when considering the influence of power system harmonics.

Measurement of the power taken by the fans and oil pumps of a Transformer

Large power transformers have auxiliary loads such as cooling fans, oil pumps, motorized tap-changers, cabinet heaters, lights, etc. The amount of power of these auxiliaries. The manufacturer measures the loads consumed at the factory and is provided with the transformer test report.

The aux. Loads can also be measured while the transformer is in service using simple hand-held power meters. For each aux. load, measure its voltage and current while operating, and then calculate the apparent power of that load.

Transformer Oil Pumps

If the transformer has oil pumps, check the flow indicators and the pump.

isolation valves to ensure oil is circulating properly. Pump motors can also have reverse rotation, and flow indicators can show that the oil is flowing. To ensure that the motors are working in the proper direction, use an ammeter to check the motor current. Compare results at full load current indicated on the motor nameplate.

If the motor is inverted, the current will be much less than the nameplate's full charge current. Check the oil pumps with a vibration analyzer if develop unusual noises Have the DGA lab check for dissolved metals in the oil and run a metal particle count for metals if the bearings are suspect. This should be done as soon as a bearing becomes suspect; bad oil pump bearings can put enough metal particles in the oil to threaten the insulation of the transformer and cause electric shock within the tank, resulting in explosive catastrophic transformer failure tank.

Transformer Fans and Radiators

Inspect all isolation valves on the top and bottom of radiators to make sure they are open. Inspect cooling fans and radiators for cleaning and fans for proper rotation. Check if it is dirty or damaged partially blocked fan blades or radiators. Fans are much more efficient if the blades are clean and turn in cold air. Normally fans blow cold air through radiators; They should not be going through the air. Check if the fans are electrically reversed (i.e. pulling the air first) through the radiators and then through the fan blades). This means that the blades rotate in hot air after passing through the radiator, which is much less efficient. Place one hand on the radiator. in front of the fans; air should come out of the radiator against your hand. Watch the blades as they rotate slowly when they are starting or stopping to determine which direction they should be turning and correct

Rotation if necessary.

Tests on bought-out components/accessories such as Buchholz relay, temperature indicators, pressure relief devices, oil preservation system, etc.

Pre-commissioning tests of the Transformer

After installation on site, the transformer also goes through other tests, performed on it, before the actual commissioning of the transformer on-site. The transformer test performed before the transformer is commissioned on-site is called the transformer pre-commissioning test. These tests are performed to assess the condition of the transformer after installation and to compare the results of all low-voltage tests with the factory test reports.

Record of observations from general physical inspection/check:

Periodic/condition monitoring tests of the Transformer

The test conducted for analysis of the transformer insulation condition by examining the transformer oil is called the DGA Test. DGA test must be conducted periodically to ensure the healthiness of the transformer for trouble-free operation of the transformer.

Condition monitoring shows the existing condition and the remaining life of the transformer. Analysis of dissolved gases provides a clearer picture of the health of transformer oil and paper insulation. The test performed to analyze the transformer insulation condition when examining the transformer oil is called DGA Test.

The DGA test should be performed periodically to ensure the health of the transformer for trouble-free operation of the transformer. The DGA results indicate the healthiness of the transformer insulation system.

Transformer Emergency tests or Online Predictive Maintenance

Online predictive maintenance services can be performed while your system remains energized, eliminating costly shutdowns. Performing Visual Inspections, Infrared Testing, and Ultrasonic Detection can help you identify when a failure may occur so you can plan an outage instead of dealing with an emergency.

This is a lovely post, I enjoy it really thanks and keep it up.

ReplyDeleteTractor

If you operate with transformers as a transformer manufacturer, transformer supplier, transformer service company, transformer user as a power consumer, or utility company, then transformer testing is crucial for you. However, with online digital marketing services you are not required to perform every type of transformer test; depending on your service category, the transformer testing technique and the tools and equipment used for the test will vary.

DeleteIf you operate with transformers as a transformer manufacturer, transformer supplier, transformer service company, transformer user as a power consumer, or utility company, then transformer testing is crucial for you. However, with online digital marketing services you are not required to perform every type of transformer test; depending on your service category, the transformer testing technique and the tools and equipment used for the test will vary.

DeleteI have a friend who is an electrical engineer. We used to be together. We were in a course at university. He had the Best Coursework Writing Service. He used to be with me at that time. Nowadays he has shifted to UK. and now day to teach me How many types of transformers are there?

ReplyDeleteIf you're wondering, "Can I use a text editor to rewrite my essays?" more here , you're not alone. Text editors can be used to fix spelling and grammatical errors. They also make writing quicker and easier. The best text editors can meet most of your writing needs within one tool. Plus, they'll help you rewrite your research in a professional manner, free of mistakes.

DeleteI am a fan of transformers movies and due to which I also stopped here to read the full blog, otherwise I was here to get the humanities assignment help and still needing that!

ReplyDeleteIt reminds of my COVID-19 period when I always used to play PUBG. You know, I even used to find online service to Complete My Online Class For Me so that I can give enough time to the PUBG. Seriously, you know it was one of the best days I got in my life.

ReplyDeleteThere are several sorts of tests that may be performed on transformers, each with its own set of benefits and drawbacks. We will compare and contrast the three most frequent forms of transformer testing in this section:

ReplyDeleteThis is a great article! I'm glad to see that transformer type tests are being routine tests. I'm sure this will help to improve the quality of the products.

ReplyDeleteIf you're wondering, "Can I use a text editor to rewrite my essays?" more here , you're not alone. Text editors can be used to fix spelling and grammatical errors. They also make writing quicker and easier. The best text editors can meet most of your writing needs within one tool. Plus, they'll help you rewrite your research in a professional manner, free of mistakes.

ReplyDeleteThis polish isn't own that I would really NEED. It's a very interesting polish, but not really my colors I guess best homework Writing services uk

ReplyDeleteYour guide looks amazing, is that procedure really work, actually I am professor in college, and want to get upgradation, also provide online assignment help services.

ReplyDeleteThis polish isn't own that I would really NEED. It's a very interesting polish, but not really my colors I guess best homework Writing services uk

ReplyDeleteIf you want a little more exfoliation, you can do that before using this mask because it brightens the skin and improves hotel girls karachi near me

ReplyDeleteoverall skin tone more than it exfoliates.

This guide on the latest technologies like transformers and other tech, I was actually here to find a reliable hnd assignments help and I guess your educational guide will be helpful for me indeed.

ReplyDeleteThis guide on the latest technologies like transformers and other tech, I was actually here to find a reliable hnd assignments help and I guess your educational guide will be helpful for me indeed.

ReplyDeleteWe Provided You with the best designer in the US for your Business, experts in Logo Design, website design, Graphic Design, PHP Design, UI/UX Design, and Development. We offer different pricing packages as per requirements.

ReplyDeleteVisit: https://logoleagues.com

I think Web Creators Hub are the top logo designers in USA

DeleteTransformer Type Tests Routine Tests and Commissioning Tests Procedure" provides valuable guidance on conducting tests for transformers. It covers essential aspects of routine and commissioning tests.

ReplyDeleteRegarding cash for cars removal Sydney it refers to a service where individuals can sell their cars for cash in Sydney. It is a convenient option for those looking to dispose of their old or unwanted vehicles while receiving instant payment.

This is a nice article gald to read it well , MCA live transfer leadsare a valuable resource for businesses in the Merchant Cash Advance industry. These leads are generated through real-time calls, ensuring immediate and direct contact with potential customers. With MCA live transfer leads, businesses can increase their conversion rates and maximize their sales opportunities.

ReplyDeleteElectrical engineers and experts in the industry might benefit from this thorough reference on Transformer Type Tests, Routine Tests, and Commissioning Tests Procedure. It specifies crucial processes and actions to guarantee transformers' optimal performance. It's a great reference because of the thorough explanations and step-by-step methodology. Precision in daily activities, such as using CBD products, can help lead to a well-balanced and healthy lifestyle, much as accuracy is essential when testing electrical systems. For best results, both engineering and wellness necessitate meticulous attention to detail and a methodical approach.

ReplyDeletehttps://www.cbdproductsforyou.com

The comprehensive examination of transformer type tests encompasses routine tests, where insulation resistance, turns ratio, and winding resistance are meticulously assessed. Additionally, commissioning tests are performed, ensuring seamless integration into the power system by evaluating parameters like insulation levels, load performance, and protective relay settings. A professional ghostwriter can adeptly elucidate these procedures, providing a clear understanding of the meticulous testing processes involved in guaranteeing optimal transformer functionality.

ReplyDeleteWhat i don’t understood is in reality how you’re no longer really a lot more well-appreciated than you may be right now. You are so intelligent. You already know thus significantly on the subject of this subject, produced me in my view consider it from a write my assignment lot of various angles. Its like men and women are not interested until it is something to do with Woman gaga! Your individual stuffs nice. At all times handle it up!

ReplyDeleteAre you searching for the perfect logo that encapsulates your brand's essence? Look no further! Our comprehensive guide showcases the top logo design companies in the industry for 2023. Explore innovative designs, unparalleled creativity, and exceptional expertise. Make an informed choice for your business and create a lasting impression with a logo that speaks volumes.

ReplyDeleteThis article on transformer type tests and routine tests is incredibly informative! The breakdown of different tests and their significance provides a clear understanding. It's a valuable resource for anyone looking to grasp the intricacies of transformer testing.

ReplyDeleteformularios de divorcio no disputado en virginia

Engaging blog post discussing the rise of remote work and its implications for work-life balance. A thought-provoking read for modern professionals

ReplyDeletePrefabricated Houses

Stainless Steel Gate In India

Asbestos Cement Sheet Manufacturer In India

Portable Cabins Supplier In India

I have thought so many times of entering the blogging world as I love reading them. I think I finally have the courage to give it a try. Thank you so much for all of the ideas!

ReplyDeletethe best genuine services for writing political science assignments. Finding reliable experts who specialize in political science assignments can greatly enhance the quality of your work. Online Academic writing help

ReplyDeleteRestoro Download has a strong focus on user privacy and safety. Secure encryption is used for scanning, and personal information is never shared or kept without the user's permission. So, people can trust this software to fix their problems without worrying about their private data getting out.

ReplyDeleteThe shannara chronicles commander tilton leather jacket”, inspired jacket presents one more unique collection for you, which will enhance your level of dressing, the black color and full fitted jacket commander tilton is here for you, this product is made up from original quality of leather and vast quilted soft viscos black lining. Variety of sizes you will get from small to double extra-large. There is a stand collar style, with use of multiple maroon straps throughout the jacket, and full sleeves with round open cuffs. It is highly suggested to you as per its look from far away which will add more sunshine in your personality, do not think too much about it, just buy it and start wearing. Your level of comfort will be too high.

ReplyDeleteThe shannara chronicles commander tilton leather jacket”, inspired jacket presents one more unique collection for you, which will enhance your level of dressing, the black color and full fitted jacket is here for you, this product is made up from original quality of leather and vast quilted soft viscos black lining. Variety of sizes you will get from small to double extra-large. There is a stand collar style, commander tilton with use of multiple maroon straps throughout the jacket, and full sleeves with round open cuffs. It is highly suggested to you as per its look from far away which will add more sunshine in your personality, do not think too much about it, just buy it and start wearing. Your level of comfort will be too high.

ReplyDeleteThe shannara chronicles commander tilton leather jacket”, inspired jacket presents one more unique collection for you, which will enhance your level of dressing, the black color and full fitted jacket is here for you, this product is made up from original quality of leather and vast quilted soft viscos black lining. commander tilton Variety of sizes you will get from small to double extra-large. There is a stand collar style, with use of multiple maroon straps throughout the jacket, and full sleeves with round open cuffs. It is highly suggested to you as per its look from far away which will add more sunshine in your personality, do not think too much about it, just buy it and start wearing. Your level of comfort will be too high.

ReplyDelete"LogoVent: A Fusion of Creative thinking and Accuracy. We provide unique and powerful visual identities that are suited to your brand as our niche of expertise in Custom Logo Design USA

ReplyDeleteWeb Creators Hub offers best logo design services in the USA, bringing brands to life with creative and professional designs. Their team actively listens to client ideas and transforms them into unique logos that stand out. They focus on delivering clean, modern, and impactful designs that reflect your brand’s identity. With their expertise, they make the process smooth and enjoyable, ensuring you leave with a logo you love. Highly recommend their services for anyone looking to elevate their brand!

DeleteWeb Creators Hub offers top-notch logo design services in the USA, bringing brands to life with creative and professional designs. Their team actively listens to client ideas and transforms them into unique logos that stand out. They focus on delivering clean, modern, and impactful designs that reflect your brand’s identity. They make the process smooth and enjoyable, ensuring you leave with a logo you love. Highly recommend their services for anyone looking to elevate their brand!

Deletehttps://webcreatorshub.com/logo-design-agency.php

Thanks for the information nice website Thotslife.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteTo overcome the writing difficulties, students can get IT Management Assignment Help from experts. Many writing services in the USA have teams of experts who can provide comprehensive guides to students for writing academic papers. They can support students in the best way to create a top-notch quality solution within the deadline. They provide the easiest solution even for complex topics in a simple and effective way. It helps students to submit quality solutions for the paper and enhance better understanding of the subject.

ReplyDeleteFashion has become very popular nowadays and especially jackets. Check out this famous Evelyn Wang "Everything Everywhere All At Once" Punk Jacket and its quality is excellent.

ReplyDeleteI have to say that your information is helpful. Reading it is something Custom medal enjoy.

ReplyDeleteI'm employed at Graphic Design Eye. The company has custom packaging design for top-notch designs that fit your budget.

ReplyDeleteI'm employed at Graphic Design Eye. The company has custom packaging design for top-notch designs that fit your budget.

ReplyDeleteGood article thanks for sharing! On the off chance that you are a transformer maker or transformer client, you should produce or buy a predesigned and indicated transformer to satisfy your client or your prerequisite where a transformer quality test or transformer dispatching test is significant. So to affirm the details and exhibitions of an electrical power transformer you need to go through various testing strategies. If you need any legal help, kindly visit our page. criminal defense lawyer charlottesville va

ReplyDeleteThanks for sharing this information content with us. This is Steve, I'm author at Boring Magazine and we're working on the same topics I'm here when I was doing some research.

ReplyDeleteThanks for sharing your valuable insights, This is Imran Zahid, the Founder of Boring Magazine (aka www. theboringmagazine.com) a content knowledge domain just like Meta Press.

ReplyDeleteThe Cleveland Browns Long Sleeve Hoodie is that perfect expression of comfort and spirit for a die-hard Browns fan. It is in premium fleece material, meant to keep warm and durable, which perfectly designs it for game days or casual outings. The pullover-style closure and hooded collar add design that any football lover can express to show team spirit.

ReplyDeleteGreat breakdown of transformer type and routine tests! This is incredibly useful for anyone in the electrical engineering field. By the way, if you're building a brand or business in this niche, having a strong identity is essential. I recently used affordable logo design services to create a logo that truly stands out. Highly recommend for anyone looking for expert branding solutions!

ReplyDeleteNice post. I was checking constantly this blog and I am impressed! Extremely helpful information specially the last part I care for such info a lot. I was seeking this particular information for a very long time. Thank you and good luck. vinilos decorativos

ReplyDeleteDiscover The Bark Media, your premier Best Series Streaming for unforgettable events and quality entertainment.

ReplyDeleteDiscover The Bark Media, your premier Best Series Streaming for unforgettable events and quality entertainment.

ReplyDeleteUseful

ReplyDeleteNVQ assignment help is essential for learners working toward National Vocational Qualifications in various sectors like health and social care, construction, business, and childcare. These assignments require a combination of practical evidence, written work, and reflective accounts aligned with specific performance criteria. Many learners struggle with structuring their answers, understanding the assessment standards, or gathering relevant workplace evidence. NVQ assignment help at MyAssignmenthelp provides help on meeting unit requirements, writing clearly and professionally, and submitting high-quality portfolios. Whether you're studying at Level 2, 3, or beyond, the right support can make a big difference in your progress and confidence throughout the qualification process.

ReplyDeleteIf you need Assignment Help in Malaysia, Assignmenthelppro is the go-to service! They offer exceptional original and well-researched solutions for a wide range of subjects, including business, law, nursing, engineering, and more. Whether you're struggling with essays, research papers, dissertations, or case studies, their professional writers ensure proper formatting, thorough research, and timely delivery. The best part? Their services are reasonably priced, making academic support accessible to all. I highly recommend Assignmenthelppro for anyone looking for reliable and high-quality assignment help in Malaysia!

ReplyDeleteThanks for this detailed and valuable article! I really appreciate the clear explanations and practical tips you’ve shared. If you’re into gaming, you might enjoy exploring Ok Win Game — it’s one of the best gaming platforms I’ve come across. Use the Okwin Game Gift Code for amazing bonuses, download through Okwin App Download, and don’t forget to check out the Okwin Lottery for exciting opportunities!

ReplyDeleteThanks for this detailed and valuable article! I really appreciate the clear explanations and practical tips you’ve shared. If you’re into gaming, you might enjoy exploring Ok Win Game — it’s one of the best gaming platforms I’ve come across. Use the Okwin Game Gift Code for amazing bonuses, download through Okwin App Download, and don’t forget to check out the Okwin Lottery for exciting opportunities!

ReplyDelete